“Safety is not an intellectual exercise to keep us in work. It is a matter of life and death.”

Gro Harlem Brundtland

In the chemical industry, where the risk of accidents can have catastrophic consequences, maintaining operational safety is paramount. Predictive maintenance AI is increasingly recognized as a critical tool in this sector, enabling companies to anticipate equipment failures and system anomalies that could lead to safety hazards. This article explores the integration of predictive maintenance AI in chemical plants, supported by industry data and case studies, to illustrate how companies can bolster safety and efficiency.

Significance of Predictive Maintenance in Chemical Manufacturing

Chemical plants involve complex processes where equipment failures can lead to serious safety risks, including chemical leaks, fires, and explosions. Predictive maintenance AI helps mitigate these risks by ensuring that all machinery and systems operate within safe parameters.

Industry Insights:

- The American Chemistry Council reports that the chemical industry spends over $20 billion annually on maintenance. Predictive maintenance can reduce these costs by up to 30% while significantly decreasing the risk of hazardous incidents.

- A study by McKinsey found that predictive maintenance could cut safety incidents by up to 14% annually in high-risk industries, including chemical manufacturing.

Real-World Application:

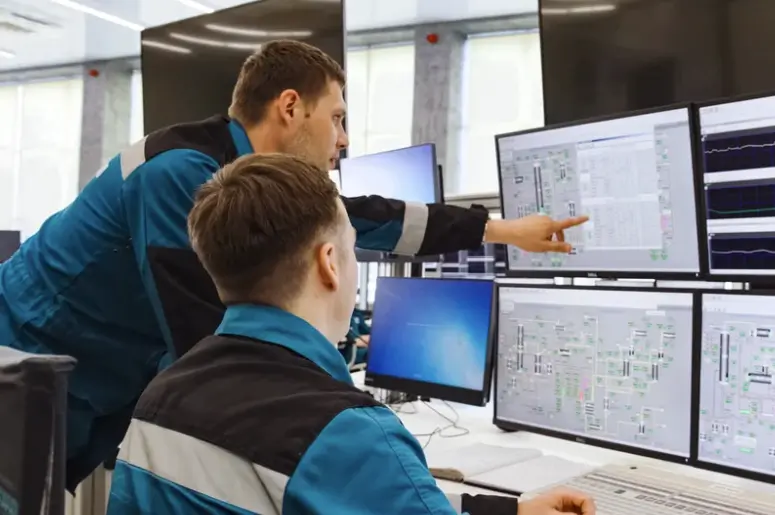

- A leading global chemical company implemented predictive maintenance AI across multiple plants to monitor critical systems such as reactors and pressure vessels. The AI system uses sensors to collect operational data, which machine learning algorithms analyze to predict potential failures. This approach has led to a 40% reduction in unplanned downtime and a significant improvement in safety metrics.

How Predictive Maintenance AI Promotes Safety in Chemical Plants

Proactive Hazard Prevention: Predictive maintenance AI allows for the early detection of equipment anomalies that could lead to safety hazards. By proactively addressing these issues, chemical plants can prevent accidents before they occur, ensuring a safer working environment.

Optimized Maintenance Schedules: AI-driven insights enable chemical plants to conduct maintenance based on actual equipment conditions rather than fixed schedules. This not only ensures that maintenance resources are used efficiently but also reduces the likelihood of equipment failing during operation, which could have severe safety implications.

Extended Equipment Life and Reliability: Regular maintenance informed by AI analytics helps extend the life of machinery, reducing the likelihood of failures that could pose safety risks. Moreover, it ensures that equipment operates reliably and efficiently, contributing to overall plant safety.

Challenges in Implementing Predictive Maintenance AI in the Chemical Sector

Integration with Complex Industrial Systems: Implementing AI in environments with complex chemical processes and legacy systems presents significant challenges. Custom solutions that can integrate seamlessly with existing operational technologies are essential.

Data Management and Analysis: Effectively implementing predictive maintenance AI depends on the availability and accuracy of operational data. Chemical plants need robust systems to collect, store, and analyze data from various sources, ensuring that AI models receive high-quality inputs.

Regulatory and Compliance Issues: The chemical industry is heavily regulated, and any new technology must comply with existing safety and environmental regulations. Ensuring that AI implementations adhere to these regulations is crucial for legal compliance and operational continuity.

Leveraging Advanced AI Solutions for Enhanced Safety

Advanced predictive maintenance solutions tailored to the unique needs of the chemical industry can simplify the adoption of AI technologies. These solutions provide comprehensive tools for monitoring, analysis, and reporting, enabling chemical plants to enhance safety and efficiency.

By offering scalable and customizable platforms, advanced solutions ensure that predictive maintenance strategies can be adapted to meet the specific needs of each facility. Continuous support and updates ensure that these systems remain effective and compliant with industry standards, helping chemical plants achieve their safety and operational goals.

In conclusion, predictive maintenance AI is a vital technology for enhancing safety in the chemical industry. By enabling proactive maintenance and hazard prevention, AI technologies help ensure that chemical plants operate safely and efficiently. With the right predictive maintenance solutions, chemical companies can reduce risks, improve compliance, and safeguard their operations against potential disruptions and accidents.